I’m not sure I’m counting right when I say 18 degrees of freedom. Really counting it and figuring out which ones are independent of each other would probably give me a headache. Either that or make a good problem for a college mechanical engineering class, which I’m not qualified to teach.

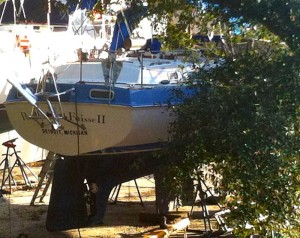

I’ve got an arch to build. I’ve built two legs and a curved top. I want to attach it to Flutterby so that it is properly aligned with the back of my hard dodger to support three big solar panels. I had built all three pieces by the time I left this boatyard last summer. I had started trying to figure out how to fit them together then, but left before I finished.

When I returned, I was dreading this complicated set of decisions, so I decided to make easier progress on the hard dodger, as all the complicated decisions like this were already made. having done some good work there, I’m back at it again.

The saying goes “measure twice, cut once.†If you know how long a piece you want, you only have one measurement. Double-check it and then cut it! That isn’t my problem.

I put the three parts temporarily over the cockpit, about where they will go. Then I started measuring. Two measurements doesn’t even get me started. I’ve got two plumb bobs to check if each leg is at the same angle fore-and-aft. and also inboard/outboard. I’ve got two more to check the height and position of the arch. I’ve got marks where the outside edges of the solar panels will go on both the arch and the back of the dodger. I’ve got rails balanced between the two of them so I can check both that the arch and the back of the dodger are parallel, and that the solar panel edges are at a right angle to both arches. I can check the angle of the dodger, the arch, and the connecting rails with a level. To tweak things right, I’ve got six strings tied to the legs and tugging them in various opposing directions.

Last week, I did something big. I decided to drill four holes. The day before yesterday, I actually drilled two holes in the base of each leg. Doing it took a bit of creative work with a drill press, and it was while an amazing front was blowing through, complete with a tornado warning on my phone and the lights flickering a couple times.

Yesterday I did the next step. Put everything back up together, and drilled two holes into the boat, and put in screws. Boom. Now the bottom of each leg is located in two dimensions. Four degrees of freedom nailed down. 14 to go (plus or minus a few!)

Deciding how to decide can be the toughest part.

The actual decision is easier, but can be tedious. You have been warned. If your eyes glaze over a couple sentences into the next paragraph, just give up and skip to the last paragraph!

Today I went back and re-measured a couple things. Discovered that two measurements didn’t agree with each other. The two rails that should be parallel weren’t perpendicular to the same thing. Scratched my head a bit. Re-measured and found out that the marks where I was locating the outside rails were not the same distance apart on the arch that they were on the dodger. Oops. Fixed that. Noticed that my beam is twisted a bit, with one corner up about a half inch compared to the other. Found that I could clamp it flat without too much effort, and figured I’d do that when I glued it all together. Noticed that while the wheel is vertical, and that the stainless pipe on the front of the binnacle is NOT vertical. Now i know which one to look at when I’m checking the legs.

And I decided that I don’t care if the legs are exactly vertical or not. My masts aren’t at the same angle either, and the boat doesn’t float upside down from that. I still need to set that angle, and I’ve decided I’ll do it based on where it puts the front of the solar panels with respect to the front of the dodger instead. It matters more to me, and it is easier to measure. Double-win!

Another decision. In the morning I’ll re-check a bunch of measurements, and drill two more holes and put in two more screws. I’ll have the fore-and-aft angle of both legs set. Two more degrees of freedom nailed down. I’m chipping away at it. Pretty soon I’ll be epoxying the whole thing together!